Indicators

PCD Plasma Tests

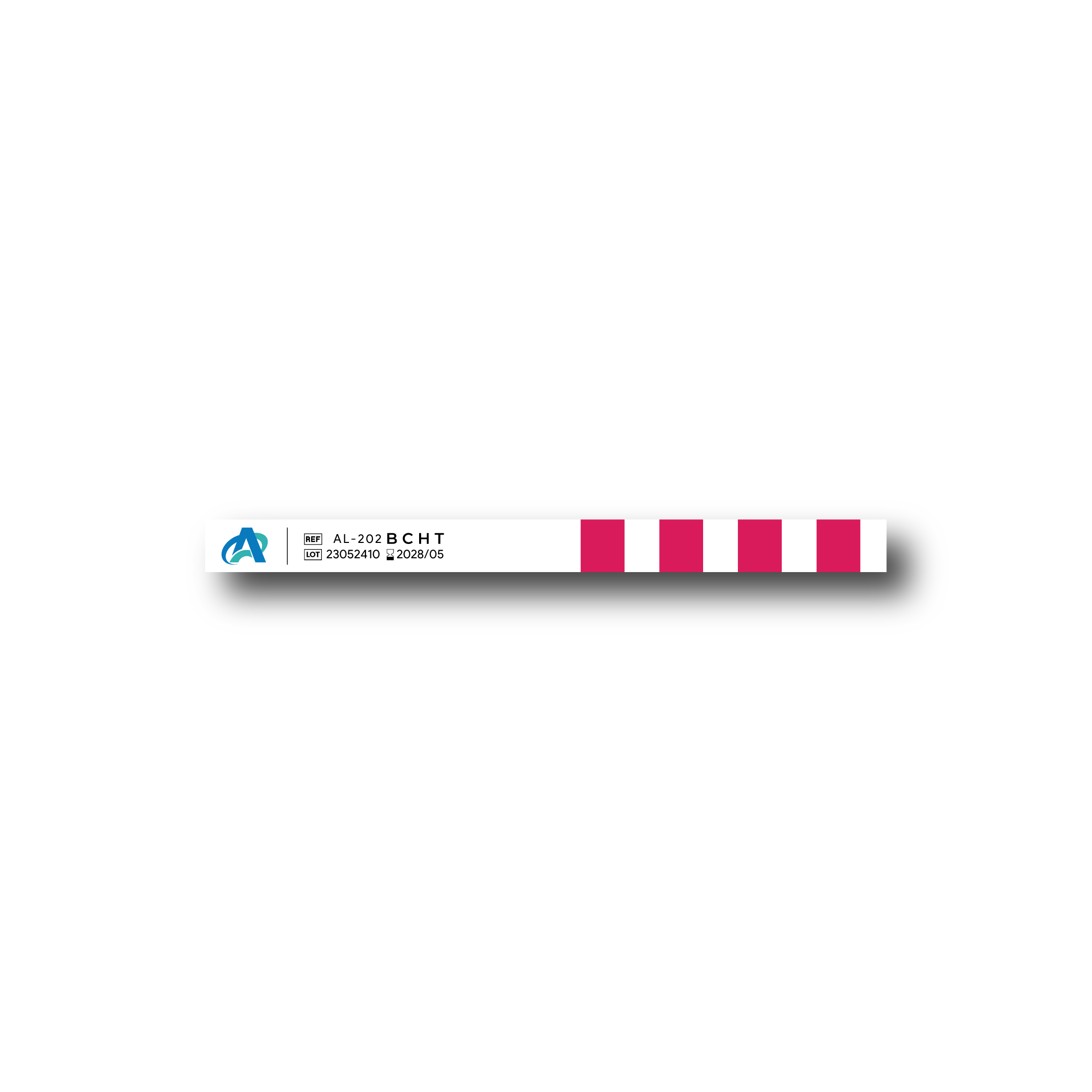

PCD Plasma Tests (Process Challenge Devices for Plasma Sterilization) use internal chemical indicators designed to simulate the most difficult conditions for sterilization. The indicators undergo a distinct color change (color change as product IFU) when exposed to properly operating plasma sterilization cycles. A complete color change demonstrates that the sterilization parameters — such as the presence of reactive plasma species — were met throughout the simulated load.

Key Features:

- High Sensitivity: Designed to mimic the most challenging load conditions in plasma sterilizers.

- Clear Color Transition: Distinct and easy-to-read color change for quick interpretation.

- Non-Toxic Chemicals: Safe for operators and compliant with modern healthcare environmental standards.

- Pre-assembled Device: Ready-to-use process challenge device (PCD) containing the indicator inside a specially designed holder.

- Traceable: Lot numbers and labeling for easy documentation and traceability.

Technical Specification

- Sterilization Method: Low-temperature plasma sterilization (e.g., Hydrogen Peroxide Plasma).

- Indicator Type: Type 2 Chemical Indicator (specific for plasma sterilization).

- Operating Conditions:

- Temperature range: typically, 45–55°C

- Sterilant: Hydrogen Peroxide vapor/plasma

- Recommended cycle types: Standard cycles based on specific sterilizer models

- Shelf Life: 5 years under proper storage.

- Storage Requirements: Store at 15–30°C, away from light, humidity, and chemical contamination.

Intended Use

PCD Plasma Tests are intended to challenge the sterilization process by simulating a hard-to-sterilize device or load. They are used to verify the efficiency of plasma sterilizers on a routine basis, typically:

- Daily before use of sterilizers.

- After maintenance or repair of sterilization equipment.

- During validation or qualification of sterilization processes. Healthcare facilities rely on PCDs to ensure that critical instruments and medical devices receive effective sterilization and maintaining patient safety.

Advantages

- Reliable Monitoring: Confirms sterilizer performance with a higher level of assurance.

- Easy Interpretation: Fast, unambiguous color changes simplify; training and reduce user error.

- Enhances Patient Safety: Ensures that even the most challenging parts of a load are properly sterilized.

- Supports Compliance: Meets hospital protocols and international sterilization monitoring standards.

- Saves Time: Pre-assembled and ready to use, reducing preparation time.

Product Code: AL202